Industry news

Expertise in the use of plastic flight cases

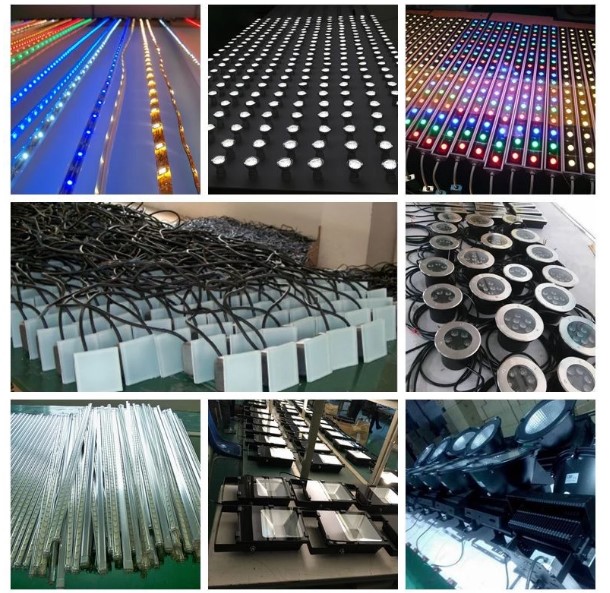

The development trend of plastic flight cases has given assistance to many companies. Flight cases are professional utensils used to hold valuable items. In recent years, the led industry has achieved a very good development trend with the assistance of flight cases. You must study hard for the application of the flight case.

A flight case with an effective design plan can not only better maintain the goods, but also improve the product level, decorate the appearance of the product and the practical effect of simple application process.

The shell has different design schemes and materials, and different operation methods. For example, items below the net weight should be placed according to the nuclear cargo capacity of the box design. Generally, the air box should be used under normal temperature and all normal transportation conditions; if there are special requirements, the installation is too heavy or necessary For applications in natural environments with high temperature, high temperature, and low temperature, please indicate the regulations when designing the plan. The interior designer will use different raw materials based on the matching data and information to ensure that the air box is used in all normal applications under the net weight and natural environment. life

The lifting components of the LED flight case are more applicable after being upgraded

In addition to the parts mentioned, many additional lifting components are necessary to make a flight case.)

L-shaped support frame: can improve the robustness of the whole shell.

Moisture-proof leather pad: The moisture-proof leather pad installed under the wheel well can make the shell achieve better moisture-proof effect. The shell for outdoor performances must be modified.

Wheel plate lifting plate: The wheel plate lifting plate is installed to better improve the load-bearing level of the shell and improve the service life of the wheel plate and wheels.

Square tube steel: Generally installed under the machine cover and wheel plate, the effect is to make the shell stronger and firmer under the condition of bearing the left and right forces.

Honeycomb cardboard: The common air boxes are all made of wood straight hair plywood, but the board of the new generation of air boxes is composite honeycomb cardboard. The benefits of this type of board have the following aspects: good firmness, which is generally said to be strong anti-skid; it is a new type of environmentally friendly material, and this shell can be used except for the wheel plate, wheels and hardware Recycled raw materials; the application has a long service life. Under all normal applications, the use time can be 5 to 8 years, which is 2-3 times that of the general air box.

Today's air box has many changes. The emergence of different functions has made it more and more concerned. The development trend of air box has replaced the traditional wooden box, and its excellent maintenance effect has been praised by the people.

Categories

Latest News

- Flight case manufacturers: Wha2021-01-18

- Huizhou Xinyiyi Technology Co.2021-01-16

- Expertise in the use of plasti2021-01-18

- Flight case manufacturer Huizh2021-01-18

- The role of LED flight case2021-01-18

Contact

CONTACT USContact:Zoe

Phone: +86-18720940320

Email: zoe@xyyflightcase.com

Add:Baiyun Road Huizhou City,Guangdong

+8618720940320

+8618720940320